Liquid Level Sensor

By Megha Parolkar on September 20, 2019

BeginnerIntroduction: Liquid Level Sensor

The fastest-growing industries change its requirement at every passing hour and demands level instruments that maintain standard quality with lower cost. Sapcon is a trustworthy partner to fulfill the demands of level measuring devices and considered as one of the efficient choices.

How does a Liquid Level Sensor works?

The working principle of liquid level sensor depends on the type of technology selected. Sapcon has an array of liquid level sensors that are based on Vibrating Fork, Capacitance, RF Admittance, and Conductivity principle. These are the principles which can be useful in liquid type of application media:

- Vibrating Fork: The vibration type level switch works on the tuning fork principle which vibrates at its natural frequency in the absence of material. The vibrating fork level sensors are available with hygienic mountings that support to mount the level sensor in a hygienic environment. The compact size and fast switching feature of this device make it fruitful for packaging machines.

- Capacitance: The capacitive level switch works on the capacitance principle which detects the changing value of capacitance. The properties of liquid material are precisely taken into account while designing the capacitance based level sensor. The Twin Probe and Still Well arrangement plays crucial role in these capacitive liquid level switches for material having lower dielectric media.

- RF-Admittance: The admittance based level switch works on the capacitance measurement principle with heavy build-up. These admittance based level sensors provide exceptional services even in sticky media. The designing part of the admittance level sensor is introduced with "Shield" which identifies the difference between coating and the real material.

- Conductivity: The conductivity based level sensor; also known as water level sensor which is specially designed to sense the water level. These water level sensor is generally mounted in water tanks where water is stored in large quantity.

Liquid Level Sensor Types

The liquid level sensors are broadly categorized into two parts:

- Liquid Level Switch - It is also known as Point Level Switch which determines the level only at specific points. These types of level sensors are used to detect the level at high or low points. These types of level measuring devices can be helpful to prevent overflow and dry run conditions.

- Liquid Level Transmitter - It is also known as a Continuous Level Transmitter which continuously measures the liquid. This type of level sensor monitors the level at every certain period and gives real-time results.

Product Selection: Based on Application Media

Different types of level instruments are available for level detection but before selecting the sensors, the exact type of application media should be known for betterment of output and process.

- Sticky Media

- Conductive Media

- Corrosive Media

- Foaming Media

Sticky Media

Material that can adhere to the surface of the instrument or create a coating on the probe of the level sensor is known as sticky material. Viscosity is the main parameter used to identify whether the material is sticky or not.

Examples

Ketchup

Paint

Honey

Recommended Products

Coat-Endure

RF Admittance Level Sensor

Compact coat-immune admittance level switch for sticky solids, pastes and slurries.

SLA Series

RF Admittance Level Sensor

Compact coat-immune admittance level switch for sticky solids, pastes and slurries.

Conductive Media

It give resistance to flow an electric current and it causes short circuits when comes in contact with the metal directly.

Examples

Water

Milk

Juices

Recommended Products

Elixir

Vibrating Fork Level Sensor

Vibrating Fork Liquid Level Switch suitable for level detection in storage tanks, mixing containers etc.

SLC Series

Capacitance Level Sensor

Capacitance based level switch offers level detection solution for non-sticky slurries and liquids.

SLW

Conductive Level Sensor

SLW can be used for level limit switching applications for single/two point action for conductive liquids.

Capvel-ICT

Capacitance Level Sensor

RISC based processor to perform all complicated jobs of evaluating the level out of the capacitance.

Corrosive Media

A highly reactive material which damages the external body directly or through chemical reaction is known as corrosive material. Acids and Bases are the most common types of corrosive material.

Examples

Chemicals

Recommended Products

Elixir

Vibrating Fork Level Sensor

Vibrating Fork Liquid Level Switch suitable for level detection in storage tanks, mixing containers etc.

SLC Series

Capacitance Level Sensor

Capacitance based level switch offers level detection solution for fine, coarse, non-sticky slurries and liquids.

Foaming Media

Liquids that build foam on the surface of the material are known as foaming material and require detection for precise level measurement.

Examples

Brewery

Milk

Paint

Recommended Products

Coat-Endure

RF Admittance Level Sensor

Compact coat-immune admittance level switch for sticky solids, pastes and slurries.

SLW

Conductive Level Sensor

SLW can be used for level limit switching applications for single/two point action for conductive liquids.

Product Selection: Based on Parameters

Temperature

Liquid materials are processed at high temperature which requires standoff arrangement and insulation protection to isolate sense and ground to protect the level instruments.

- PTFE Insulation

- Ceramic Insulation

Recommended Products

Coat-Endure

RF Admittance Level Sensor

Compact coat-immune admittance level switch for sticky solids, pastes and slurries.

SLA Series

RF Admittance Level Sensor

Compact coat-immune admittance level switch for sticky solids, pastes and slurries.

SLC Series

Capacitance Level Sensor

Capacitance based level switch offers level detection solution for fine, coarse, non-sticky slurries and liquids.

Capvel-ICT

Capacitance Level Sensor

RISC based processor to perform all the complicated jobs of evaluating the level out of the capacitance.

SLW

Conductive Level Sensor

SLW can be used for level limit switching applications for single/two point action for conductive liquids.

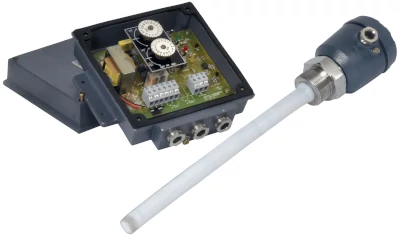

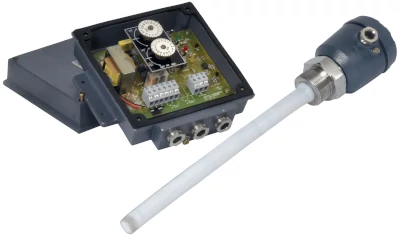

MPILC

Liquid Level Transmitter

MPILC consists of an electronic evaluation unit, an insert and a probe.

Hygiene

Hygiene is the critical requirement of Dairy and pharmaceutical industries as it deals with perishable material that are sensitive to contamination. To meet the hygienic standard following points should be taken into account while designing the level instruments.

- Surface Finish

- Geometry Considerations

- Mounting Arrangement

Recommended Products

Elixir-T-Uni

Vibrating Fork Level Sensor

Compact tubular vibrating fork level switch suitable for all kinds of liquids.

Elixir

Vibrating Fork Level Sensor

Vibrating Fork Liquid Level Switch suitable for level detection in storage tanks, mixing containers etc.

For more details on hygienic requirements, refer EHEDG Certification for Fork Level Sensor article.

More articles on Intro Level Sensor