Man-made Fibre

Globally, India is the second largest manufacturer of man-made fibres which shares about 4% of resultant output to country's GDP. The man-made fibres are produced from chemical component named "Polymer" whose properties are changed during its manufacturing.

Applications

Storage Chip Silo

The PET/ POY chips are the primary form of a polymer directly used to make fiber and yarn. These plastic chips are stored in large silos and hoppers to transfer it for further processing. For calibration-free solution vibration type level switch Vital is well suited where as for cost-effective solution rotating paddle level sensor orbit will be perfect.

Wet Chips Hopper

From storage silo the chips are entered into blender. After blending it is stored in small hopper called wet chips hopper whose level will be regulated automatically with the help of level measuring instruments. For compact size solution vibration level switch Vital will be effective and for vibrating rod level sensor refer Vibrosonde.

Dry Chips Hopper

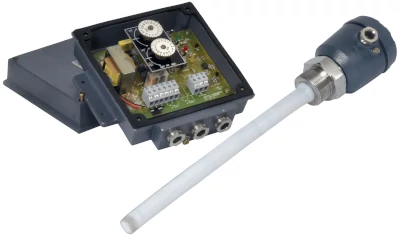

From wet chips hopper, POY chips are transfered to the dryer system where it is dried through hot air to maintain the moisture level and are stored in a separate hopper named dry chips hopper. The automation drying process requires the Capvel-ICT level transmitter for continuous monitoring throughout the process.

Spin Finish Tank

The dried chips are melted at 270℃ to make a liquid syrup-like solution. The molten liquid is fed into the container called spinneret and an external force is applied to its tiny holes to produce fibre. The sticky liquid chips require SLA Series admittance level switch which has build-up immunity.

Water Tank

Water is stored in large tanks to constantly supply of the water in the manufacturing plants to operate the process. These tanks are used with SLW type level measuring device to prevent overfill condition.

Industry Expert

Surendra Kushwah

Business Development

Industry Vertical: Chemical and Man-made Fibre

Schedule a Callback