Product Templates Item Code: ETU

Operating Principle

The working principle of vibrating fork level switch is based on tuning fork’s natural frequency measurement. A specially shaped tuning fork is continuously vibrating at its natural frequency using piezo-electric elements and detecting the changes in frequency in the presence of application media. The pressure applied on diaphragm drives the tuning fork's tines apart from each other and return to their original position when the pressure is removed. As the material level increases and comes in contact with the vibrating fork tines, the frequency of oscillation of tuning fork level switch dampens or decreases as it covered with the liquid application media. The change in frequency is detected by the microprocessor leading to a switching decision. The threshold frequency is set to match the natural frequency of vibrating fork level switch under water.

Benefits

Designed & Manufactured in India

In-house Research and Development keeps pace with new age applications, outputs and standards

EHEDG Certification

EHEDG certified vibrating fork level switch is suitable in hygienic applications.

Proven Performance

Successful installations in challenging applications for dairy and pharmaceuticals processes.

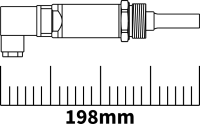

Compact Size

Fits fine within insulation pockets on applications silos. Helps in reducing fabrication cost.

Hygienic Finish

Surface Roughness Average of 0.8 µm for the surface of the vibrating fork level sensor bypass contamination process.

Immune to Foam Build-up

Ignores foam build-up on tuning fork. Useful in dairy applications where foam build up is excessive.

Resilient High Temperature Operation

Suitable for applications involving bubbles, steam and material flow at 150°C.

Service Friendly Plug-in Connection

Industry standard valve plug-in connection, easy to install and ready to use.

External Circuit Testing

A simple diagnostic tool to check output connections and start diagnostics.

CAD View

Applications

Brewery Production Plant

To maintain the taste of beer over a decade appeals stringent operational conditions with hygienic pipe fittings to avoid adulteration throughout the process. These severe environmental conditions in brewery production plants provide proper aroma and taste to the beer.

Elixir-T-Uni fork type level switch with standard hygienic surface finish (0.8 µm) is suitable in a beer manufacturing plants to prevent contamination.

Dairy Industry

Dairy processing plants engage milk for a longer period to include in other processes. Continuous processing of milk in tanks requires clean-in-place(CIP) operations to restrict contagious bacterial growth. These operations demand compact liquid measuring instruments that should be fitted in small pipelines and mixing tanks.

The compactness of our liquid level indicator makes them flexible enough to fit in small containers. The EHEDG certification is a surplus benefit to maintain the hygiene in entire operations.

Packaging Machines

The Food & Beverage sector is the biggest consumer of automated packaging machines followed by the pharmaceuticals sectors. The rapid growth of the packaging industry needs an automation process sensor to sense the appropriate filling of application material.

Our vibrating or tuning fork sensors are immune to foam build-up which not only detects the foam but also provides correct switching decisions to improve process efficiency.

Valuable Insights

EHEDG Certification

Sapcon's vibrating or tuning fork sensor are certified by EHEDG and can be used in hygienic environment.

AS-Interface for Fork Sensor

Our level switch tuning fork series is accessible with "AS-Interface" to reduce cable complexities and save cost.

Liquid Level Sensor

Our liquid level indicator is used as one of the Liquid level measurement techniques to detect any liquid media.