Poultry & Cattle Feed

Animal feed industries like fish, poultry and cattle feed has increased the quality standard and growing its importance with the help of latest modern technology. These modern trends make operation efficient to manage and control the production unit .

Applications

Raw Material Storage

Raw materials like wheat bran, rice bran, molasses, maize, cottonseed, mineral mixture, and bajra are stored in hoppers and silos to be used for further processing. For free-flowing materials, Vital is well-suited whereas for longer probe lengths Orbit with rope arrangements is great choice.

Cleaning

The cleaning process involves the extraction of impurities. For this, different batches of raw materials are prepared which passed through a magnet to separate impurities. Use Capvel-ICT with temperature compensation to receive stable output and Vibrosonde will be beneficial for better life span.

Grinding & Mixing

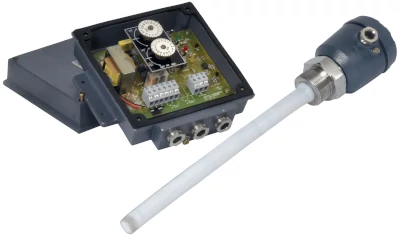

The grinder crushes the material proportionally and conveys the resultant material to the mixing section to mix the batches together. The powder forms clumps on the level sensor probe which can be detected by SLA Series.

Mollasifying

In the mollasifying section, molasses are added in fixed proportion from the pre-heated storage tank through a pump which makes the material wet and sticky. RF admittance level switch Coat-Endure with build-up immunity is a fruitful solution.

Pelletizing

Wet steam is provided for conditioning the material which improves material quality. The material is compressed to force out from a die of 6-10mm of pellets. For better temperature endurance, Capacitive level sensor SLC Series will be proven solution.

Screening & Packaging

The pellets are cooled and convey to a vibratory strainer for correct pellet sizing. The final material is stored in the large silos to being dispatched. The initial need of fast switching makes Vital profitable in packaging section.

Industry Expert