Foundry & Casting

The foundry associate with a metal casting process where combinations of metals are used to improve the strength and durability. This process deals with heating metals and non-metals at extreme high temperature by melting them and pouring them into hollow cavity molds.

Applications

New Sand Hopper

The sand arrives through vehicles in the foundry industry where it is unloaded into hoppers and silos for storage purposes. For further processing, it is mixed with additives and a bonding agent. The moisture content of sand creates a coating on the level sensor's probe. To deal with such cases, use SLA Series which has coating immunity.

Additive Hopper

The sand preparation is completed by adding additive materials like bentonite and coal dust. These raw materials are stored in large hoppers from where it is taken in an appropriate quantity for mixing. For calibration-free solutions use tuning fork level sensor Vital where as for maintenance-free solution Orbit will be advantageous.

Return Sand Hopper

The discharge sand is transferred through feeder belt conveyor to the chute from where the remaining amount of sand is returned back to the storage hopper and can be reused. Rotating level switch Orbit is useful in such applications which has flap action to discard clinging material.

Molding Sand Hopper

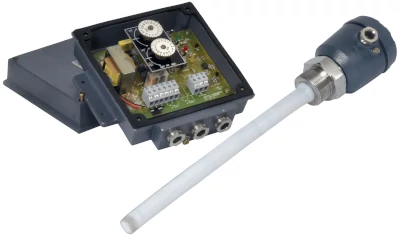

The sand is moistened with an appropriate amount of water to establish strength and make it suitable for molding. This moist sand becomes adhesive and sticks on the level sensor's probe. The problem of build-up will be resolved by admittance type level switch Coat-Endure.

Valuable Insights

Level Sensor for Solids

Various types of level instruments are used level measuring techniques to detect solid application media.

Industry Expert