Telescopic Chute

By Megha Parolkar on May 25, 2019

BeginnerIntroduction

Out-loading of bulk solids in powder or granular form is a common task in industrial plants. Various types of devices are used for unloading/loading the material at industrial plants which causes problems that compulsorily solved for human safety as well as for environmental safety. The major problems are given below:

Dust

Severe problem dust occur in open area which reduces the visibility.

Health

Health issues arise due to dust inhalation during material handling.

Loss of Material

Lack of equipment causes spillage in the storage tanks, silos & hopper.

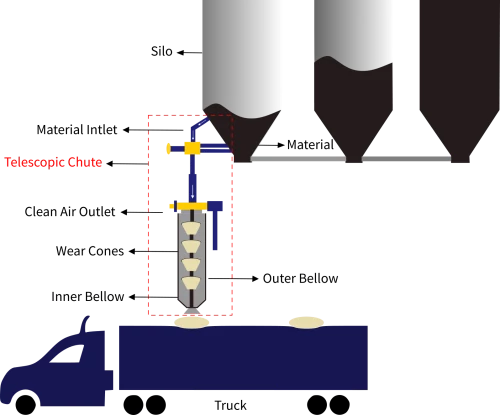

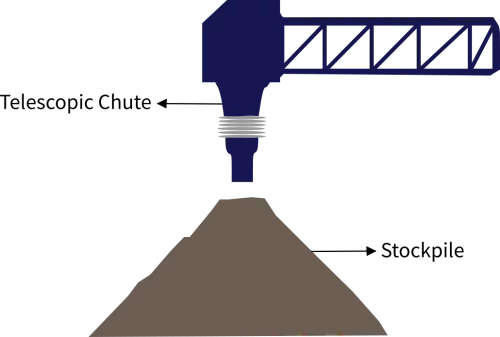

To resolve the problems given above telescopic chutes are designed. Telescopic chutes is a device help to load/unload the free flowing process material and provide dust-free and safe out-loading of material to trucks, tankers, ships and stockpiles. It has capacity to retract and expand according to the material level. They are generally mounted underneath silos, hoppers, or installed at the end of conveyors like screw feeders, elevators, or pneumatic conveying systems.

Bulk material, flowing from the upper side is transferred to the downstream vehicle, ship or stockpile efficiently without any dust emission and product loss. High efficiency of the loading operation is achieved by automating the process by using level sensors in a closed loop feedback control. Level sensors of open and closed loading chutes have different functions.

Types of Loading Chutes

- Closed Telescopic Loading Chutes

- Open Loading Chutes

Closed Telescopic Loading Chutes are used to fill the closed container like trucks and ships. At the beginning of process, the material flow is stopped and telescopic chutes are bring towards the truck inlet. After setting the chute, the material flow starts and discharges freely through inner side of chute. The air dust of the material is passed through chute and then discharged through air outlet. Level sensor is fitted at the clearance point measures the level of application media and halt the process when container is full.

In closed vehicle loading, (i.e. tanker trucks) level sensor is used for signaling when the product reaches the tanker inlet level. Loading operation is stopped when the truck is full.

Open Loading Chutes are used to fill the open truck and stockpiles. In open area bulk material are directly exposed to atmosphere causes serious health problems and dust. The telescopic chutes are laid down to the bottom then the material flows starts through the chute. Flexible dust skirt of the chute should cover the product discharging region to prevent any fugitive dust and also keep enough space for rapid product discharge. When the product level increases, flexible dust skirt should raise accordingly to provide dust-free and fast loading. Level sensors located on the chutes are continously measures the material level. The telescopic chute level rises automatically depends on the material level. After process completion, the telescopic chutes are bring back to top position.

Level Measurement Solution

SAPCON has a wide range of level sensors suitable for level detection of various types of materials having different physical and electrical properties. These sensors are based on a number of measuring principles such as RF capacitance, RF Admittance, electromechanical vibrations (vibrating fork and vibrating rod). These level sensors offer a wide choice in handling a variety of industrial bulk materials reliably and efficiently. These level sensors have been especially designed to operate in the hostile industrial environment and have a long and trouble-free track record.

For Fast Switching

Vital

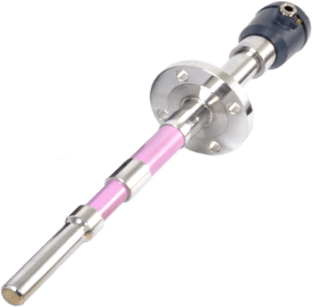

Vibrating Fork Level Sensor

Vibrating fork level switch for free-flowing solids, granules and powders.

Vibrosonde

Vibrating Rod Level Sensor

Vibrating rod type level switch for free flowing solids and grains.

For Dusty Environment

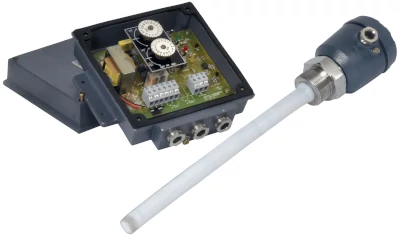

SLA Dot Display

RF Admittance Level Sensor

Suitable for longer distances between probe and evaluation unit.

SLA Series

RF Admittance Level Sensor

Compact coat-immune admittance level switch for sticky solids, pastes and slurries.

More articles on Intro Level Sensor