Level Measurement for Waste Heat Recovery Boiler

By Dhananjay Palshikar on April 23, 2021

ExpertWaste Heat Recovery System in Cement Industry

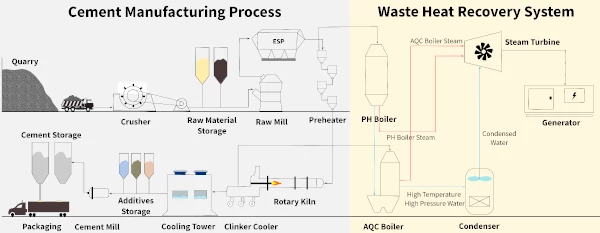

Over the last decade, awareness about environmental pollution and savings on cost have driven the adoption of Waste Heat Recovery Systems in the Cement Industry. Savings are not limited to the cost of power bills, on account of regenerating power, better utilization of fuel reduces the equipment cost which is a big capital expenditure. Successfully designed and well run WHR systems can also observe reduction in fuel usage and subsequent reduction of storage space for fuel.

Level Detection Challenges with Waste Heat Recovery Boiler

Level measuring instruments are installed at several stages in the manufacturing life cycle of cement. A brief overview of all applications covered by level sensing in cement plants can be found here, where silo level monitoring systems are used to proficiently manage low and high level sensing points. As a level sensor manufacturer, two new challenges can be identified for providing level measuring devices to WHR boilers:

- Increased Continuous Process Temperature

- Increased deposition of dust carried by pressurised hot air

Making WHR Systems useful

New cement plants are designed to accomodate WHR systems in the cement life cycle, however for the existing cement plants, retrofitting of WHR systems has been successfully explored.

It is also possible that for some WHR systems to show no actual significant improvement operational efficiency. Efficiency for WHR systems is dependent on a number of process parameters.

A level measurement solution should therefore look to increase the efficiency of the WHR system consistantly. By reducing downtime due to adjustments, failures or replacements level instruments can help contribute positively.

Point Level Detection for WHR Boiler

For adapting to the challenges posed by the WHR systems, the popular RF-Admittance Level Sensors have been upgraded to make them more reliable, more maintenance-free and more physically robust. The heavy duty rod probe of these level measuring instruments makes it fruitful for sustaining high temperature and dusty environment of cement industry.

Better Coating Immunity

Better Diagnostics

Resiliant under Temp.(>600°C)

- Better Coating Immunity:

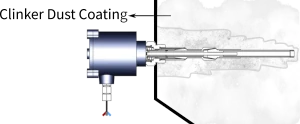

Clinker dust is a very low dielectric material in normal conditions, the sensitivity for the level measuring instrument has to be high enough for it to detect the application media. However the buildup of fine dust and occassional moisture or change in ambient temperature can disturb the capacitive reference point for the level sensor.

The micro-controller enabled hardware has the ablilty to sense has a wider range of capacitance, making easy run-time adjustment possible.

- Better Diagnostics:

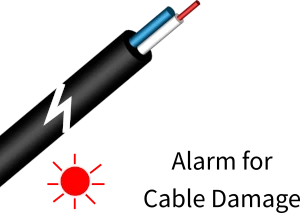

Detecting damage to the RF signal cable is an important diagnostic signal for the operations and maintainance team. The identification of the cause of failure can save crucial time in reducing the downtime.

- More Resiliant under Process Temperature above 600°C:

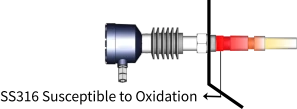

Clinker dust carried from by the hot pressurized air could be at very high temperatures. This speed of travel or dust and the temperature can wear out SS-316 material. Sapcon Instruments has successfully deployed SS-310 probes level indicators in high temperature clicker dust application.

SS-310 is more resilient to abrasion and has a higher oxidation temperature, which make the level switch last longer than level switch built with SS316.

References

- Manual on Waste Heat Recovery in Indian Cement Industry, Confederation of Indian Industries

More articles on Solutions