Soybean Processing Plant

Globally trending "king of beans"-soy is the key source of protein and vegetable oil and has a crucial place in the world's essential seed producer due to its surging demand, productivity and contribution towards vegetable oil production and feeds of poultry and fish. The manufacturing process undergoes crushing and drying operation to make variety of soybean resultant products.

Applications

Storage Silo

The starting process includes cleaning the soybean by removing impurities and drying it to approximate 7.5% moisture to enhance dehulling process. Vibration level switch Vital works well in such applications where moisture content is less.

Cracker

Beans are cracked into equal pieces by passing through roller mills. It is important to assure the consistent bean size to crack the small beans properly. The smaller beans can be stuck in vibrating forks so it's better to use admittance level sensor SLA Series.

Soya Flakes

The cracked seeds are heated to 165°F temperature with proper conditioning to achieve desired resultant in flaking process. Mechanical rollers are used to produce thin flakes and are stored in silos which need level measurement devices like SLC Series.

Husk Bunker

The flaky and bulky outer coat of soybean referred as husk or hulls which is heated to reduce their bulkiness and to destroy enzymes. This low-density material requires an orbit type rotary level sensor which has adjustable sensitivity according to the material.

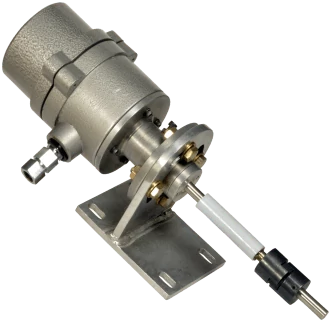

Solvent Extraction plant

The flakes are directly conveyed to the extraction plant to extract oil from soy flakes by washing it with hexane in the extractor feed hopper which uses MPILC type level instruments for level measurement purposes and for build-up immunity SLA Series will be beneficial.

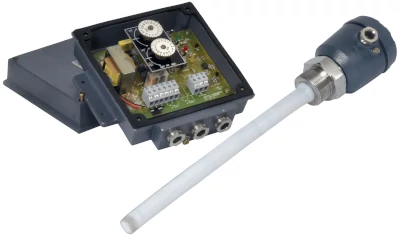

Deoiled Toaster

Once the oil is removed; the flakes are transferred to desolventizing toaster for eliminating the remaining hexane from oil and flakes. Specially designed Elefant type level transmitter is a perfect solution for this application which has a rugged design to withstand in any tough environment.

Industry Expert