Fly Ash Level Detection in ESP Hoppers

By Megha Parolkar on May 6, 2019

IntermediateIntroduction

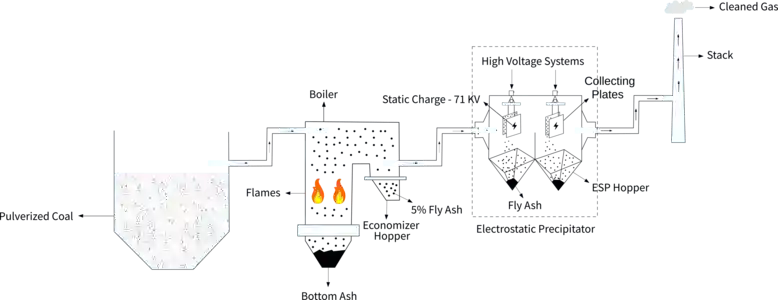

In Thermal Power Stations, some amount of ash particles are prone to get carried away with the exhaust air of the Boiler. In order to prevent these ash particles from being exhausted out of the stack, they are collected in the Economizer of the Boiler by gravity method. However, a large portion of the Fly-ash particles which can not be trapped in the Economizer are collected in the ESP Hoppers below the Electrostatic Precipitators (ESP) having high peak voltage of 71 KV on the collecting plates to polarize the Fly-Ash Particles.

Fly-Ash is thus collected in a number of hoppers below the ESPs. To prevent over-spilling of Fly-ash from these hoppers, de-ashing is performed after a fixed time interval. But this process results in high power consumption as many times the de-ashing operation takes place after the pre-fixed interval even though the hopper is not filled completely with Fly-ash. Further there is a lot of wear & tear due to moving parts of the de-ashing system.

This calls for an Automatic Level Detection System to control the High and Low Level of Fly-ash in the ESP Hoppers and start the emptying process only when the pre-set max. Level is reached. This prevents build-up of the ash particles in the portion of the High Voltage Plates where build – up could cause a short-circuit between the collecting plate and the electrode (especially under Humid conditions ) thus destroying the plate arrangement and the electrical equipment.

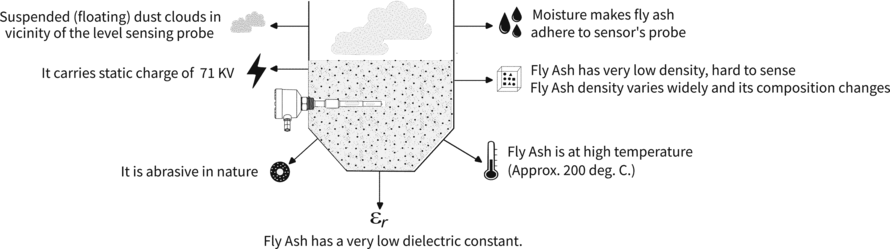

That is why the level detection of fly ash in ESP Hoppers remains a relatively difficult application in industry even today.

Challenges

Proposed Solution

The solution lies in using an RF Admittance level controller with an extra strong immuno coat Rod Probe. The Evaluation Unit measures the change of admittance accurately by using the Radio Frequency ( R.F.) techniques coupled with the coat-immunizing circuitry. The R.F. signal transmission between the Probe and the evaluation unit is via coaxial cable with driven shield arrangement. This eliminates cable capacitance & drift due to change of cable capacitance with temperature. The processed signal is used to energize or de-energize a Relay whose output contacts are available for annunciation or control. A change of Level of Fly-ash in the hopper causes a change in di-electric which in turn causes a change in admittance of this imperfect capacitor. An accurate measurement of this change affords an indirect measure of the level of fly-ash in the hopper.

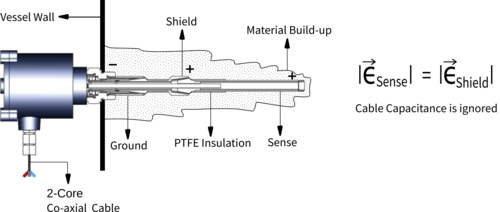

Design Concept (Immuno-coat Probe - Active Shield)

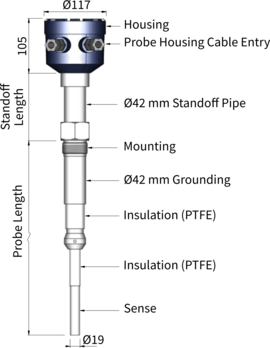

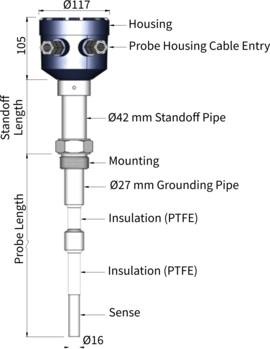

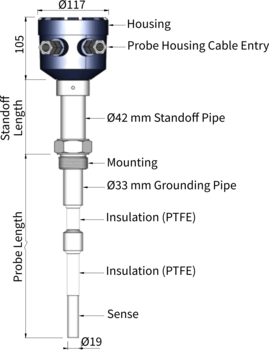

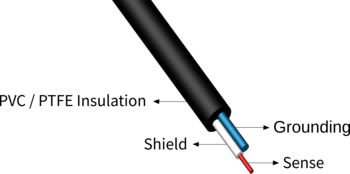

- The Probe comprises of Sense and Shield electrodes. These are electrically isolated from each other and from the Vessel Wall (Metallic Tank) by means of suitable insulators ( say, PTFE or ceramic).

- The Sense electrode and Vessel Wall serve as two electrodes of an imperfect capacitor with service material ( say, Fly Ash ) as dielectric.

- A change in material Level causes a change in dielectric which in turn causes a change in the Admittance of this imperfect Capacitor which is proportional to the Level of the material in the Tank.

- The evaluation unit measures the change of Admittance accurately by using RF techniques coupled with Coat immunizing Circuitry.

- RF signal transmission between Probe and Evaluation unit is via tri-axial cable with driven shield arrangement. This eliminates cable capacitance and drift (due to change of cable capacitance with temperature.)

- The processed signal is used to energize or de-energize a relay whose o/p contacts are available for annunciation / control.

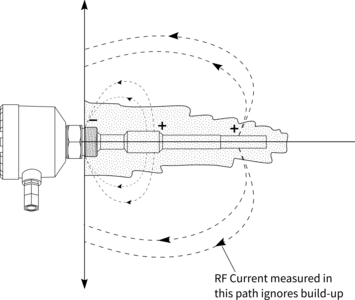

Now, how the coat immunizing circuitry works :Refer to Figure aside.

The Drive current to the Active Shield (Metal Sleeve) is at the same Frequency and Polarity as the probe. ( i.e. The Sense Probe and the Active Shield are maintained at equi-potential.) This prevents flow of RF current from Probe to the Vessel wall (Ground) in case of build up on the probe.

But when the actual bulk material in the vessel fills & touches the probe, the RF current from the Probe flows towards the Vessel Wall ( outside the saturated region for the build-up due to active shield ).

This technology will ignore build-up upto a thickness of approx. 15 – 20 mm on probe ( due to Moisture present in the material forming Lumps or due to sticky material eg. Molassis ). In any Power Plant, Fly Ash particles are air prone in the exhaust of the Boiler. In order to prevent the Fly Ash being exhausted out of the stack, a large amount is collected in the Economizer.

Mechanical Considerations

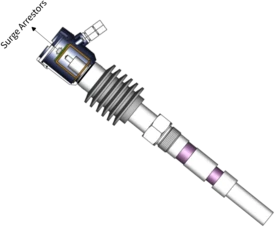

The construction of the probe along with its 2 mm thick PTFE insulation is supported by means of a tapered mechanism which makes it rugged for continuous heavy duty application.

- This also provides large sense area so as to achieve adequate change in reactance for reliable performance.

- 2 mm thick PTFE ensures firm insulation between sense and shield and between shield and ground. It can withstand more than 2.5 KV for 1 minute. Moreover this minimizes the chances of deformation when working at high temperature.

- The SS shield serves as a rigid support to the sense element for all practical purposes since the force required to bent the shield pipe is much greater than the force required to bent the sense element.

- This design also provides a rigid support to the sense element to increase the mechanical strength.

- Long Standoff ( L-300mm) is provide to protecting terminals and cable from high temp.

Electrical Considerations

The shield and sense electrode are insulated from each other and the ground. Therefore Capacitance is formed between the ground and the two electrodes with the fly ash as dielectric.

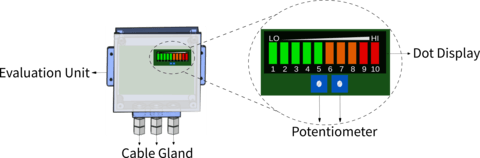

- Fly Ash density varies and its composition changes therefore the dielectric constant could vary vessel to vessel. A potentiometer on electronics evaluation unit can be used to adjust the sensor's switching sensitivity.

- Remote Calibration

- To adjust set point with potentiometer.

- With 10 LED Dot Display for sensitivity indication.

- A Gas filled Surge arrester in probe head discharges the static charge present on the fly ash as it falls in the hopper below the electrostatic precipitator preventing any possible damage to the electronics.

- The Evaluation unit measures the change of Admittance accurately by using the Radio Frequency (R.F.) techniques coupled with coat immunizing circuitry. The R.F. signal transmission between probe and evaluation unit via special co-axial cable with drain wire arrangement eliminates cable capacitance and drift due to change of cable capacitance with temperature. The processed signal is used to energize or de-energize a relay whose output contacts are available for annunciation or control.

More articles on Solutions