Operating Principle

An accurate measurement of change in admittance affords an indirect measure of the level of material in the tank. The electronic insert measures this change accurately by using Radio Frequency (R.F.) technique coupled with coat immunizing circuitry. The change is converted to a DC voltage variation, which is transmitted to the evaluation unit via a 3-core cable for further processing. The processed signal is used to energize or de-energize a relay whose output contacts are available for annunciation and/or control.

Applications

Soybean Oil Processing

Admittance level sensor supports at each stage of the soybean industry to deal with adhesive material.

- Cracking Process

- Soya Flakes

- Soya Nuggets

Man-made Fibre

The storage section of PET/PVC chips can be detected with admittance based level instruments.

- Plastic Chips

- Storage Silo

- Wet Chips Hopper

Foundry & Castings

Foundry industry deals with moisture content material which is wet and sticky.

- Bentonite

- Clay

- Sand

Valuable Insights

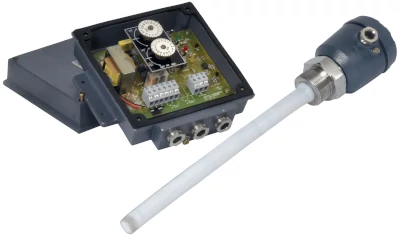

Level Sensor Probes

Depending on the temperature, RF admittance level switch's probe is differentiated to be used in extreme temperature applications.